The company has a state of art, modern R&D and Quality Control infrastructure in-house at Goa (India) consisting of a professionally competent and dedicated research team. It also engages outside professionals and agencies to support and back its R&D efforts. The company strictly adheres to the stringent norms of pharmacopoeia standards practiced worldwide.

The Quality Management System includes compliance with GLP, GCP and GEP, detailed SOP's and regulatory validation procedures to ensure Total Quality Management (TQM). Regular in-house and sponsored training and development programs are conducted to provide regulatory environment and to encourage continuous improvement in the process and testing protocols Methods and Total Quality Compliances (TQC).

Is equipped for design and development of multiple dosage form like tablets, capsules, ointments, and liquid orals.

The R&D, maintains Class-D environment and dedicated air handling units to prevent cross contamination, and thus suitable for clinical batch execution.

There are integrated, formulation development and analytical development laboratories, involved in developing generic formulations for regulated and semi-regulated markets.

The R&D transfers the developed products to the intended commercial sites through a well-defined technology transfer process.

Coordinating with the regulatory and quality team for generating data for CMC Dossiers

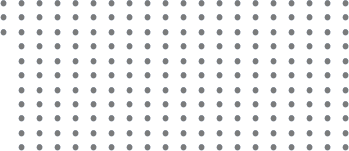

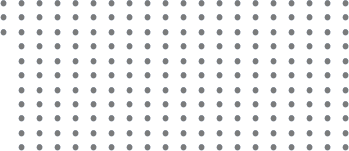

Analytical Development Laboratory is equipped to develop analytical methods for API, Excipients and Finished Products and Stability Samples.

The objective of the Analytical Development is:

Modification and suitability of compendia method